Home >> Products >> Thermal Solutions >> Thermal Interface Material >> LW-9389

A Grease Test of LW-9389 TIM Thermal Resistance and Conductivity Measurement Apparatus

STEP 1.Have 3 thickness conditions by using specialized fixtures.

Record following parameters by PC-based data acquisition software

Calculate thermal resistance (R, ℃/W) and thermal impedance (I, ℃cm²/W) of each condition.

| Th | Tc | P | Q | R | I | t |

| ℃ | ℃ | psi | W | ℃/W | ℃*cm²/W | cm |

| 80.00 | 72.90 | 40.05 | 58.20 | 0.122 | 0.787 | 0.01 |

| 80.00 | 70.00 | 40.05 | 53.76 | 0.186 | 1.200 | 0.02 |

| 80.00 | 68.03 | 40.05 | 50.70 | 0.236 | 1.523 | 0.03 |

Measuring and calculated parameters

Th: Hot surface temperature;

Tc: Cold surface temperature;

P: Press load;

Q: Heat flux;

R: Thermal resistance;

I: Thermal impedance;

t: Thickness

STEP 2.

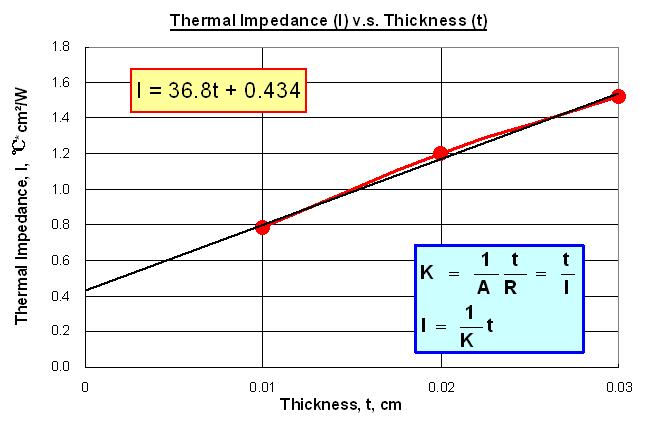

Plot the correlation of thermal impedance and specimen thickness.

Thermal conductivity (K) of the specimen: 2.72 W/m℃ can be got

by the slope after simply unit conversion.

The intercept is the contact impedance caused from the contact condition

between the specimen and meter bar surfaces.

Back to LW-9389 specification