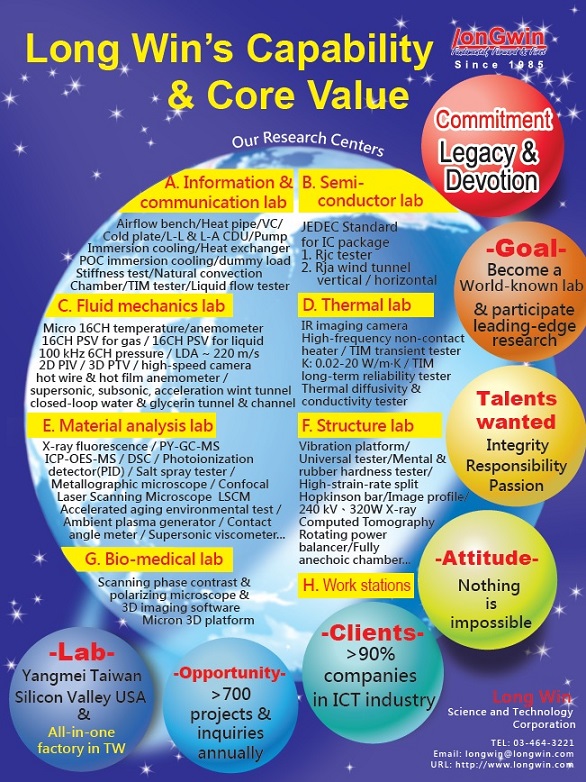

About Us

Long Win’s Core Values

■ We combine extensive and profound knowledge bases with experiments and research.

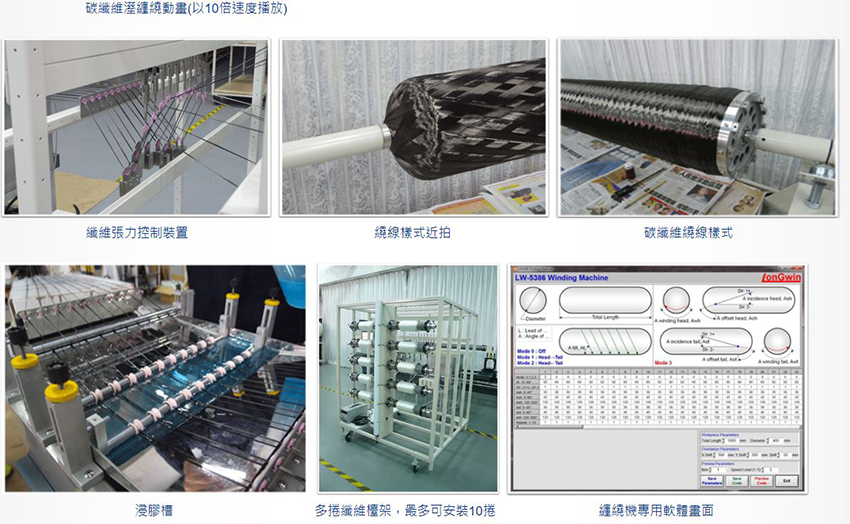

■ We practice innovative ideas through our own all-in-one factory.

We create demands.

Flow Visualization Video collection(Welcome to read)

To expect ourselves as a Fundamental, Forward, and the First Institute of Research and Development Center (3F_IRDC),

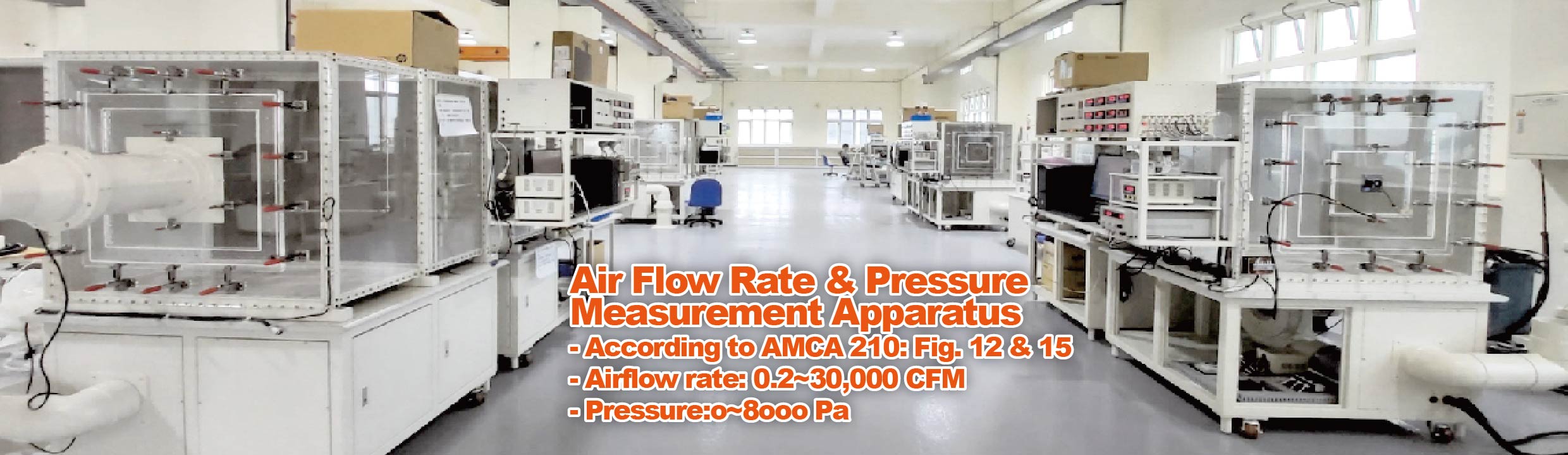

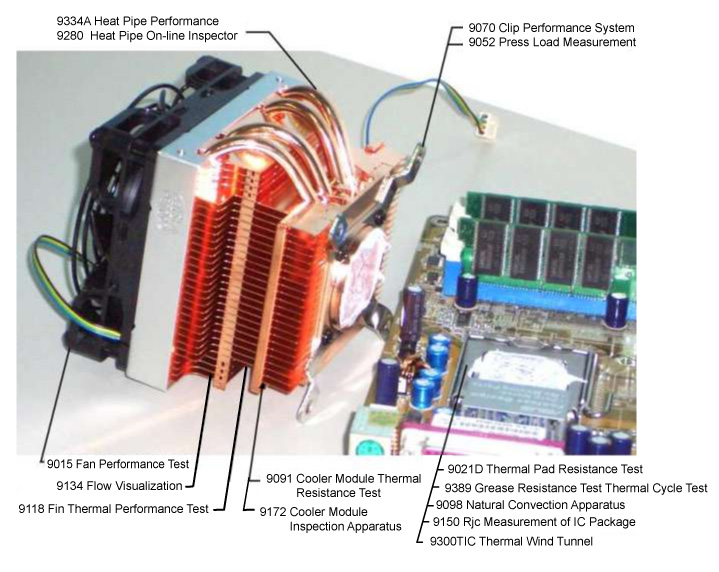

- Airflow bench for fan PQ, system resistance curve (SRC), and heat sink’s RQ performance, torque measurement, etc; 0.05~30000 CFM; >20 models

- Heat sink RQ tester; 5~800 CFM; 6 models

- Heat Pipe-HP-Thermal Performance Tester

- Micro Heat Pipe-MHP- Thermal Performance Tester

- Vapor Chamber-VC-Thermal Performance Tester

- Ultra-Thin Vapor Chamber-UTVC-Non-contact Transient and Static Thermal Performance Tester

- Cold Plate- Thermal Performance Tester

- Impedance tester for connectors, piping and Manifolds

- Liquid Burst Pressure Tester

- 4U Liquid to Liquid CDU

- 4U Liquid to Air CDU

- 8U Liquid to Liquid CDU

- 8U Liquid to Air CDU

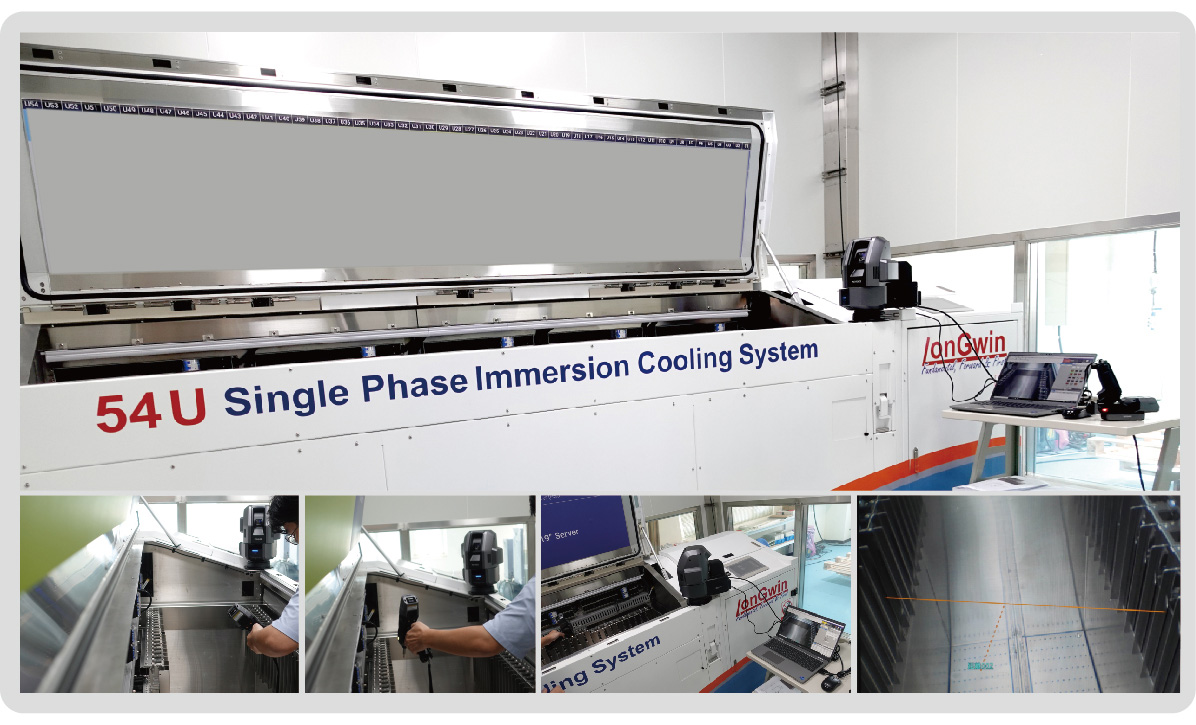

- Single-phase immersion cooling tester for heat sinks

- Two-phase immersion cooling tester for boilers

- Two-phase immersion cooling tester for condensers

- Air-liquid heat exchanger thermal performance tester; Heat loading: 1~100 kW; Airflow range: 50-10,000 CFM

- Pumper performance tester; Flow rate: 0.1-300 LPM; Pressure: 1-600 kPa

- POC single-phase immersion cooling tester 1U~24U

- POC two-phase immersion cooling tester 1U~24U

- Dummy server: 15, 30, 40, 60, 80, 100 kW

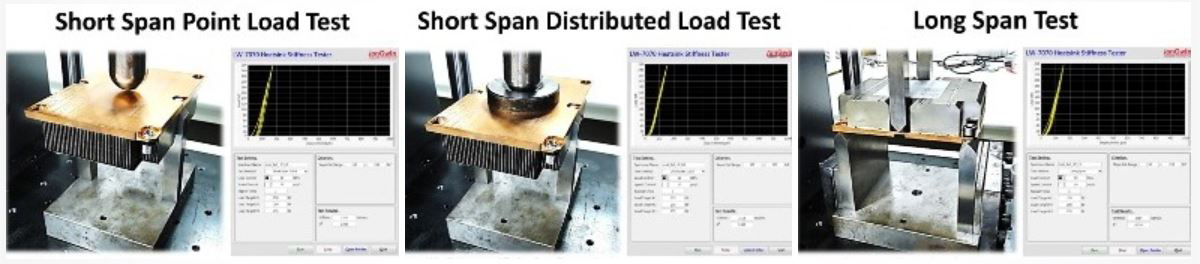

- Stiffness tester for heat sinks in servers

- Natural convection chamber: Ambient+3~70℃; Small, Standard, Medium, and Large types

- Natural convection chamber – High temp. Ambient+3~90℃

- Natural convection chamber – Ultra high temp. Ambient+3~150℃

- Natural convection chamber – Room Temp. 20~70℃

- Sunlight natural convection chamber, temperature range 40~70 ℃, Irradiance 1200 w/m2

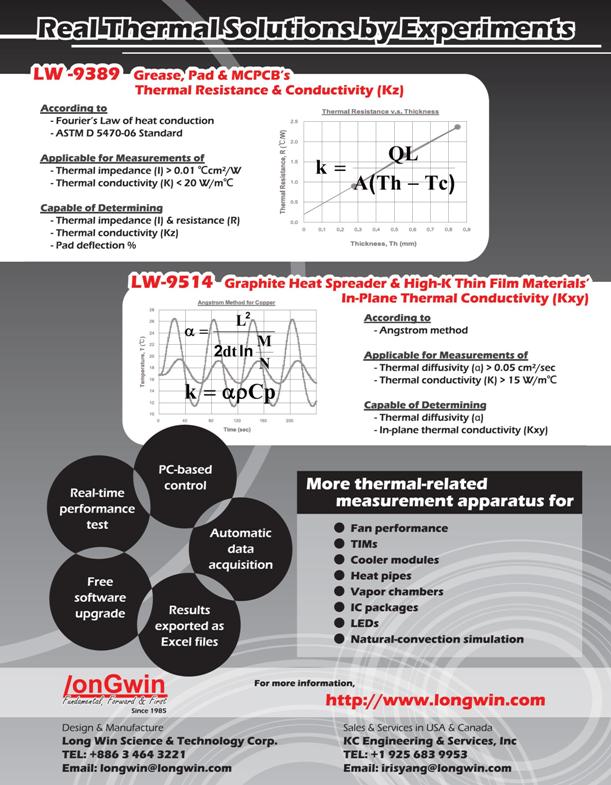

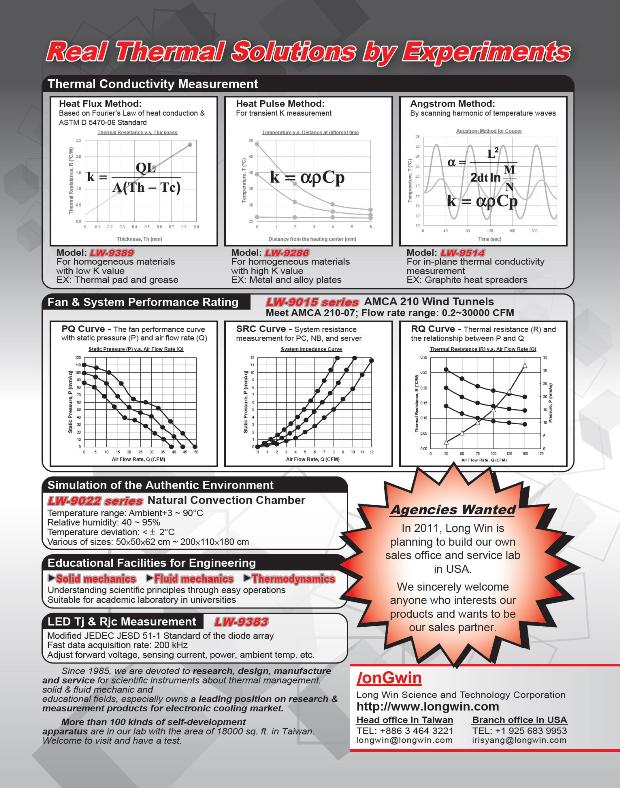

- TIM thermal impedance and conductivity tester; K: 0.02-20 WIm-K

- TIM transient and long-term reliability tester

- Thermal diffusivity tester for highly-conductive thin-film materials

- Isolated Liquid flow measurement for metal and non-metal piping; Flow rate: 0.01-60 LPM; Diameter: 3-32 mm

- Various CDU, RPU, back door performance testers

- 9 seats of walk-in chambers:To simulate data centers and to test air-cooled, L-A , L-L ,and immersion rack-level systems and rate their performance and reliability

JEDEC Standard for IC Package

- Rjc tester: 10-1,500 W

- Rja vertical wind tunnel Temperature: 20-80 °C,Wind speed: 0.5-5 m/s

- Rja horizontal wind tunnel Temperature: 20-60 °C,Wind speed: 0.5-5 m/s

- High-power semiconductor single-phase immersion thermal tester

- High-power semiconductor two-phase immersion thermal tester

- Micro 16CH temperature measurement / 16CH anemometer

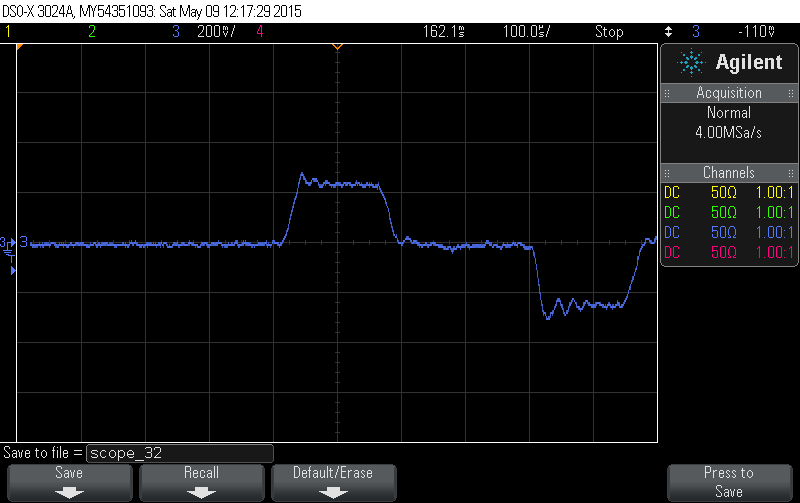

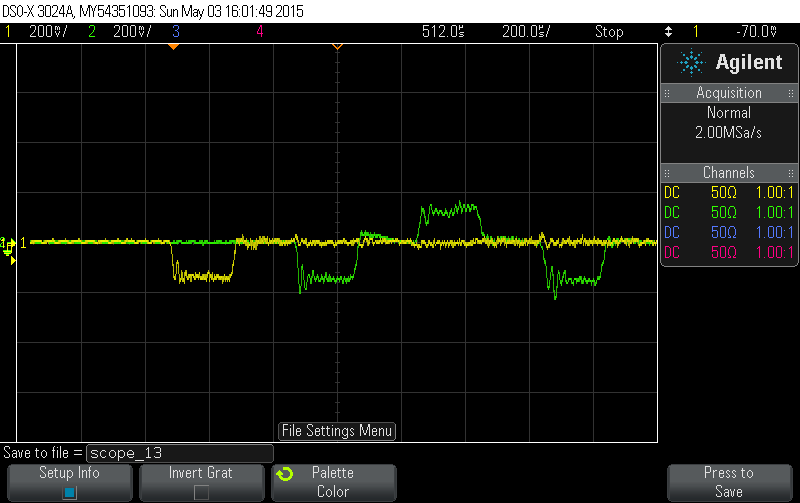

- 2K Hz dynamic 16CH PSV for gas

- 800 Hz dynamic 16CH PSV for liquid

- 100KHz 6CH Pressure Transducer

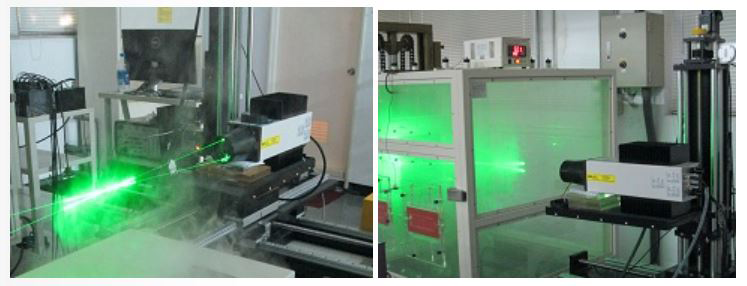

- LDA 0.01 ~ 220 m/s

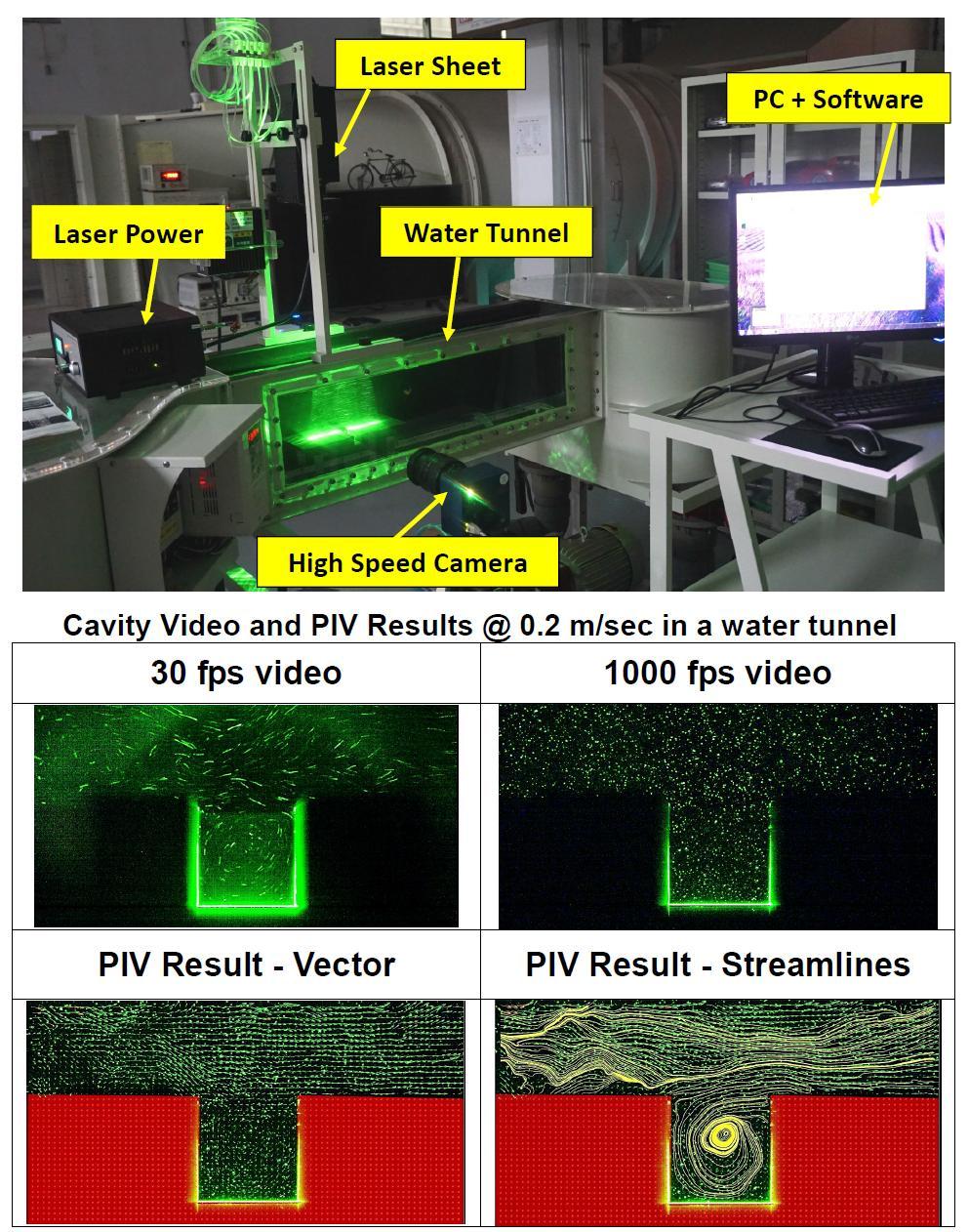

- 2D PIV, 5,000 FPS high-speed camera

- 3D PTV, 3 sets high-speed camera

- High-frequency hot wire anemometer

- High-frequency hot film anemometer

- FxㆍFy-50 NㆍFz-200 NㆍMxyz-1 Nm 6-component

- Supersonic wind tunnel 1-3.2 Mach

- Subsonic wind tunnel: Test section 1x1 m; ~60 m/s

- Subsonic wind tunnel: Test section 0.3x0.3 m; ~100 m/s

- Subsonic wind tunnel: Test section 0.2x0.2 m; ~ 30 m/s

- Closed-loop water tunnel: Test section 0.2x0.3 m; ~3 m/s

- Closed-loop water channel: Test section 0.3x0.4 m; ~0.6 m/s

- Closed-loop water channel: Test section 0.2x0.3 m; ~0.6 m/s

- Closed-loop glycerin channel: Test section 0.2x0.3 m; ~1 m/s

- Acceleration water tunnel: 2m/s, 2 m/s2 (to be built)

- Variable velocity field wind tunnel: 2-30 m/s;resolution 20mm ( in production )

- Acceleration wind tunnel: 30m/s, 15 m/s2 ( in production )

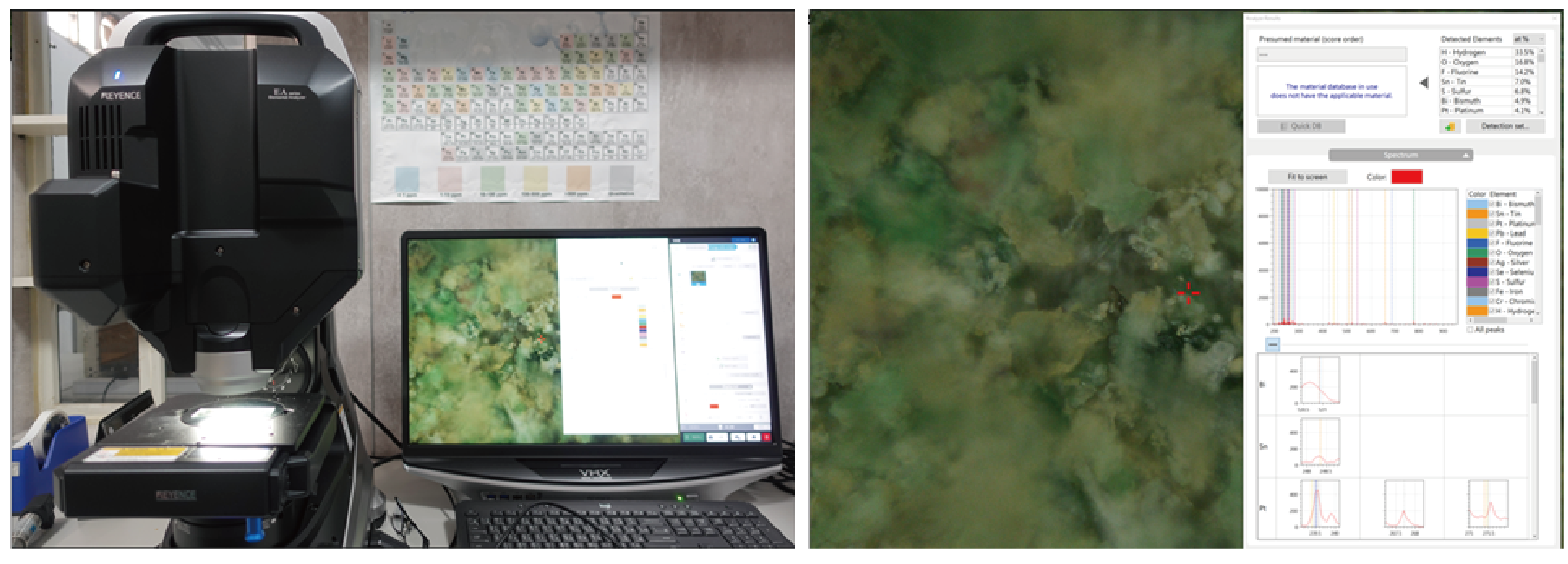

- X-ray Fluorescence

- PY-GC-MS

- ICP-OES

- DSC

- TGA

- SEM

- FTIR

- Spectrometer

- pH & Conductivity meter

- Liquid polariscope

- Salt spray tester

- Ambient plasma generator

- Contact angle meter

- Supersonic viscometer

- Liquid density meter

- Confocal Laser Scanning Microscope LSCM

- Metallographic microscope and peripherals

- Aging environmental test

- Thermal Chamber -40~1600 °C

- Photoionization Detector

- More Liquid Cooling Testers

- White Light Interferometry, WLI

- Flash point tester

- Vapor pressure tester

- IR imaging camera

- High-frequency non-contact closed-loop heater - 18W, 808nm

- TIM static thermal performance tester K:0.02-20 W/mㆍK

- TIM transient & long-term reliability tester

- Non-contact thermal diffusivity tester for highly-conductive thin-film materials

- Non-contact thermal conductivity tester

- TIM1 tester

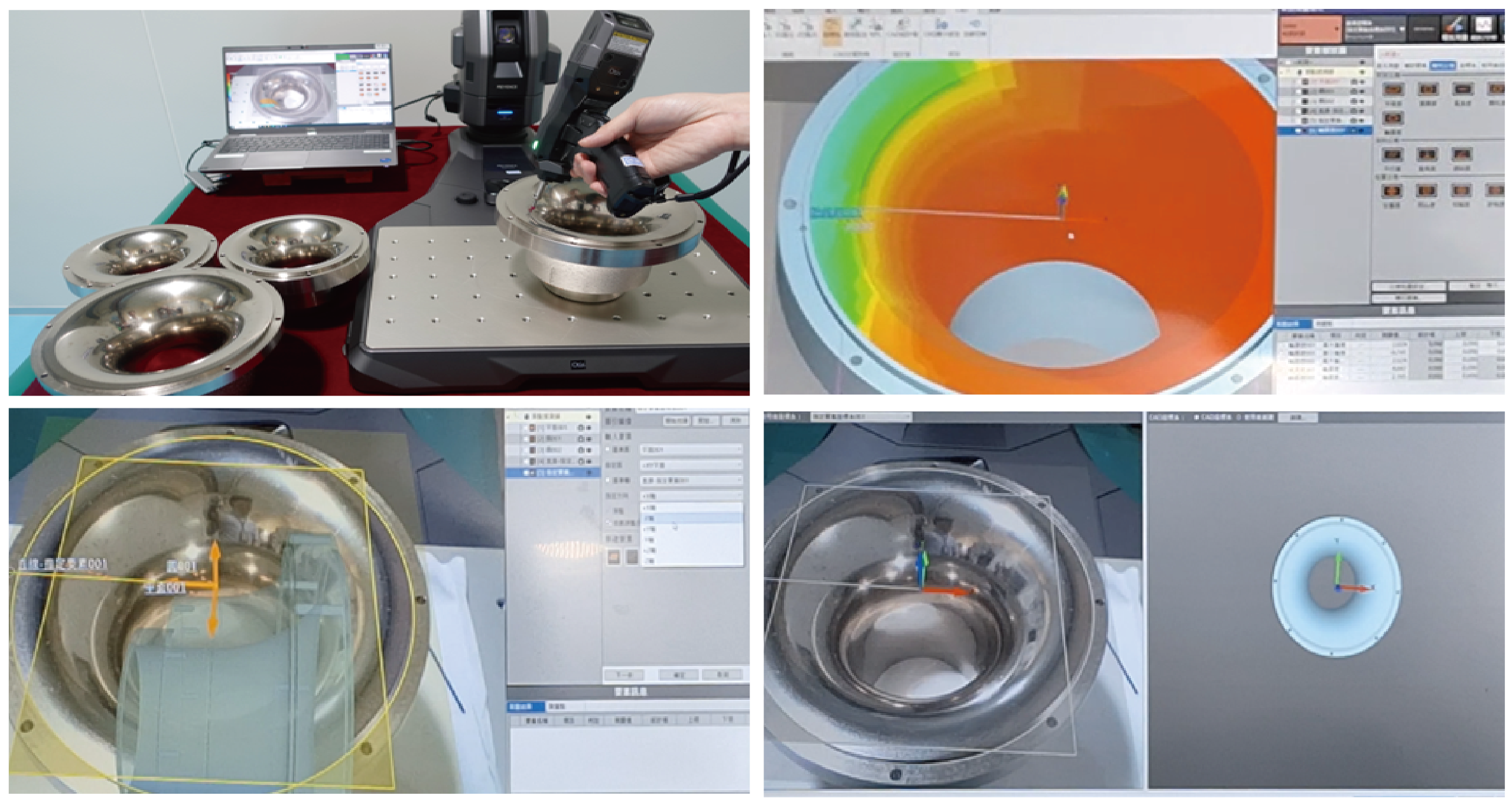

- Scanning phase contrast microscope & 3D imaging software

- Scanning polarizing microscope & 3D imaging software

- Micron 3D platform

- Vibration platform 100N; Accelerometer; Impact hammer;Measurement of natural frequency

- Universal tester: 1 MN, 50 kN, 1 kN

- Metal hardness tester

- Rubber hardness tester

- High-strain-rate split Hopkinson bar tester: Compression,tension and torsion

- Helium leak detector

- White light interferometric scanning profilometer

- Industrial stereo microscope

- 240 KV, 320 W X-ray Computed Tomography

- Rotating power balancer

- 100 MHz dynamic strain amplifier 6CH

- 200 MHz digital storage oscilloscope

- Earthquake simulation test platform: Richter Level 7; Loading 2,000 kg (to be built)

- Fully anechoic chamber (to be built)

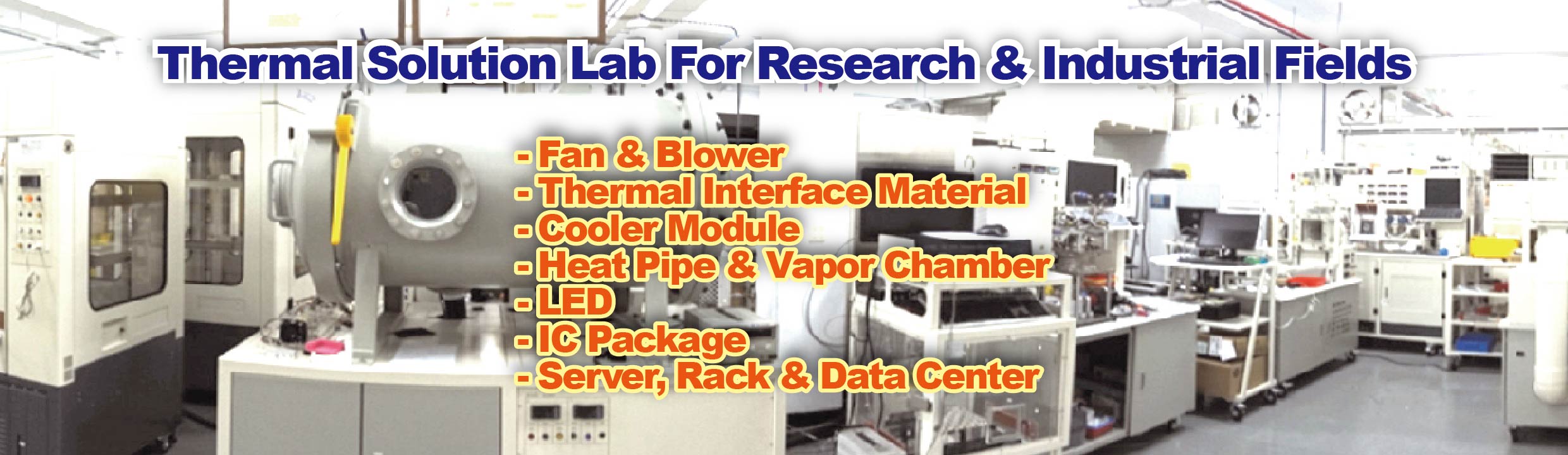

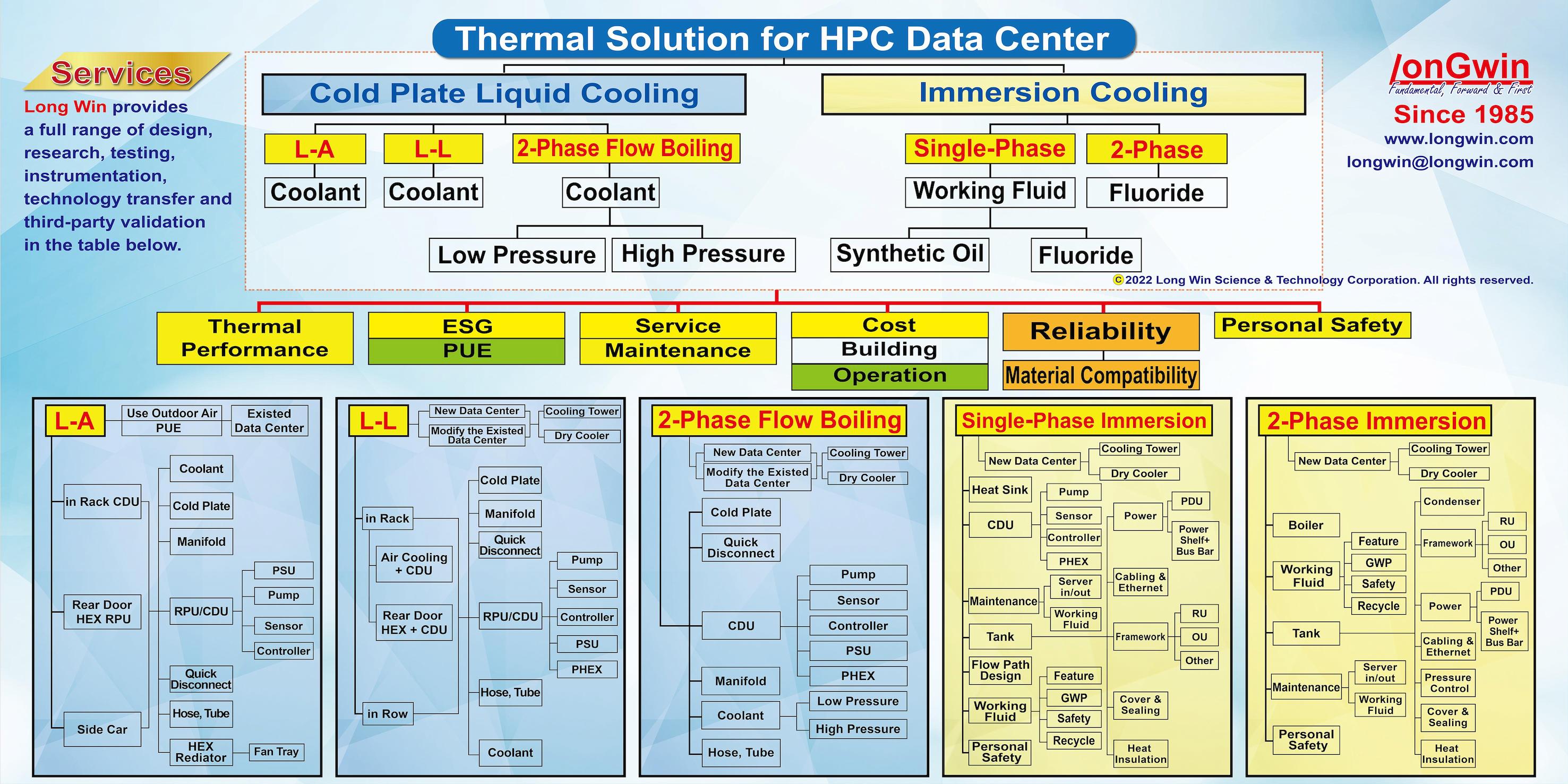

- Rack - level thermal performance test, including air-cooled, L-A ,L-L ,systems

- Immersion tank thermal performance test, including 1-P and 2-P systems

- Material Compatibility Testing

TAF 3919 / ILAC-MRA Fan Performance Test Laboratory

In August 2021, a whole new manufacturing building for all-in-one production facilities is completed. It contains all machining workshops, welding, surface treatment, piping, refrigeration, sensors, control, electrical distribution and software development. to manufacture components, products and apparatuses efficiently and accurately.

In 2022, a whole new building for research center is completed, including extended labs and a convention hall. Long Win will participate in leading-edge projects in ICT, electric cars and bio-medical industries.

Over 100 kinds of self-developing research instruments are demonstrated in our lab. Besides, we also customize research and test equipment in the thermal & flow field to meet clients’ need.

All products’ research, design, manufacture, assembling and test procedures are executed in Long Win. Our worldwide marketing instruments not only meet international standards, but also are recognized by the third party accredited laboratory for quality certification to provide professional and reliable services.

At present, our products are provided for research institutes, universities, IT, semi-conductor, automobile, air-condition, LED industries all over the world. Long Win shares the most market rate of research apparatus of thermal solutions in IT industry, and plays a very important role.

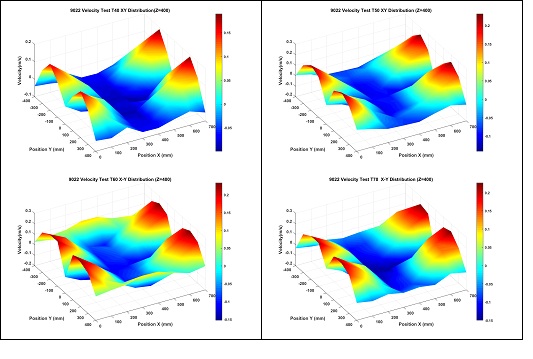

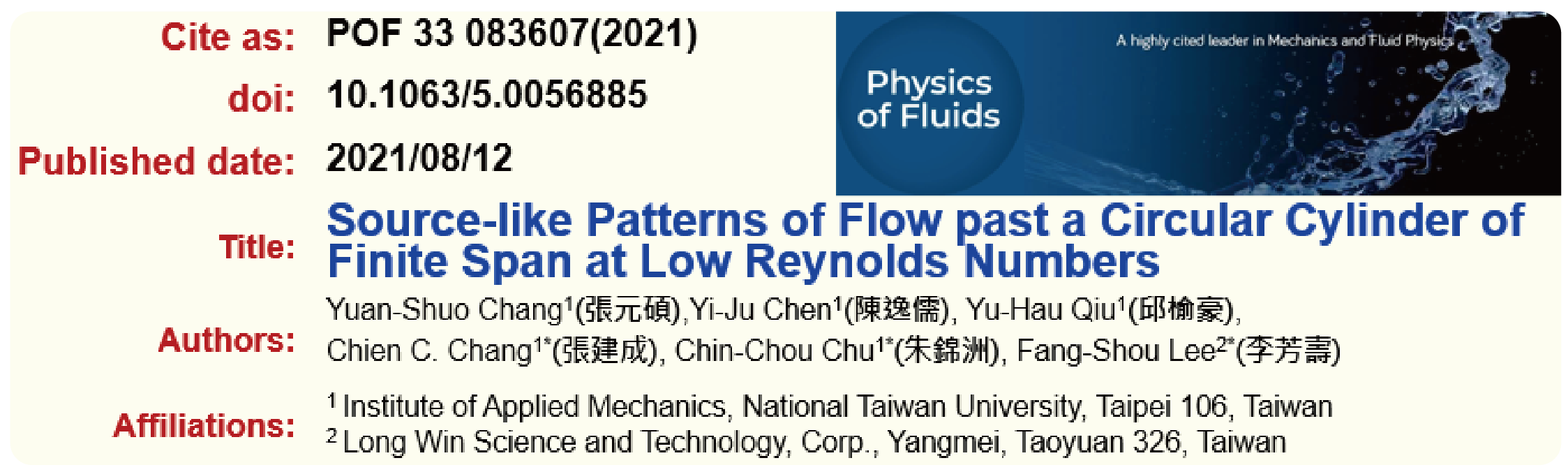

The Article Published in Physics of Fluids

Source-like Patterns of Flow past a Circular Cylinder of Finite Span at Low Reynolds NumbersTo see more eye-opening slideshows and videos...Click here to download (278 MB) Learn More